While running the metalizing plant, if we take a few seemingly small precautions, they can go a long way in ensuring optimum usage of energy, expensive materials and thereby money. And as we know, money saved is money earned.

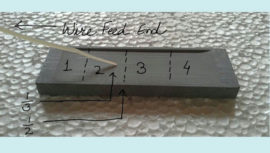

Figure 1 shows the Evaporation Boat. Aluminum wire is fed into the cavity of the hot Evaporation Boat (heated up to 1500⁰C) where –

- It melts

- Forms a small pool to fill the cavity

- Evaporates to form vapor

- Vapors stick to the substrate to make a thin coating

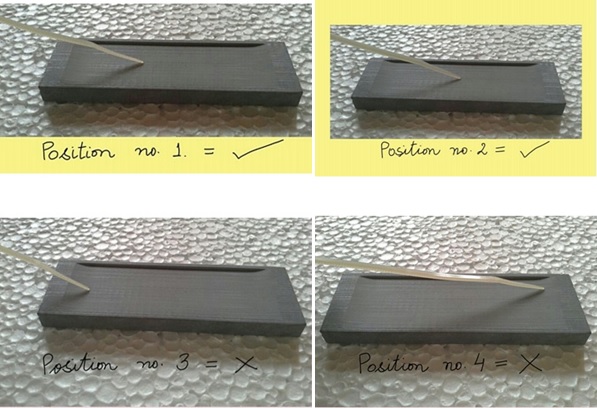

Ideally the aluminum wire should touch the Evaporation Boat between the 1/3 part and the 1/2 part from the wire feed end; never before or after this. The following photos demonstrate the right as well as the wrong position of the feed wire.

Positioning the aluminum wire too close to the edge of the Boat will not make the cavity fill up uniformly with the molten metal. This leads to –

Ø Non-uniform coating of the aluminum on the substrate.

Ø Wastage of the Al wire since this will cause excess molten metal to fall off the boat from one end.

Ø Wastage of electricity.

Ø Shorter life span of the Evaporation Boat since improper feeding of the wire will cause variation of temperature across the Boat.

Ø Faulty metalizing: When a molten pool of the metal forms in one part of the Boat’s cavity while the other part remains relatively cold, SPITTING phenomenon takes place. In SPITTING, the liquid metal overheats and bursts forth or ‘jumps’ out of the cavity in small quantities and either sticks to the vacuum chamber walls or on to the substrate.