Graphite Coating Problems:

You don't get what you want.

- The liquid smells horrible.

- Graphite slurry separates from the water and settles down.

- Dry graphite particles don't stick, create a mess and destroy the film.

- The liquid contains harmful additives.

- The suspension is priced insanely high

- Delayed delivery.

NOW GET RID OF

ALL THESE PROBLEMS

USE GRAPHINOX

World's best and more effective

Graphite Coating

by Supervac Industries LLP

99,756 Kg (100 tons approx.) Sold | 1000+ Customers | 17 Countries

99,756 Kg (100 tons approx.) Sold

1000+ Customers

17 Countries

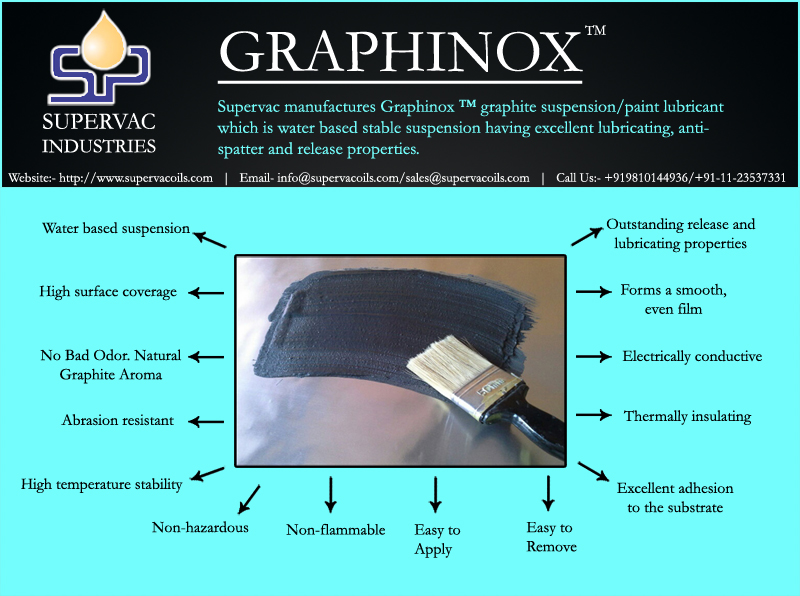

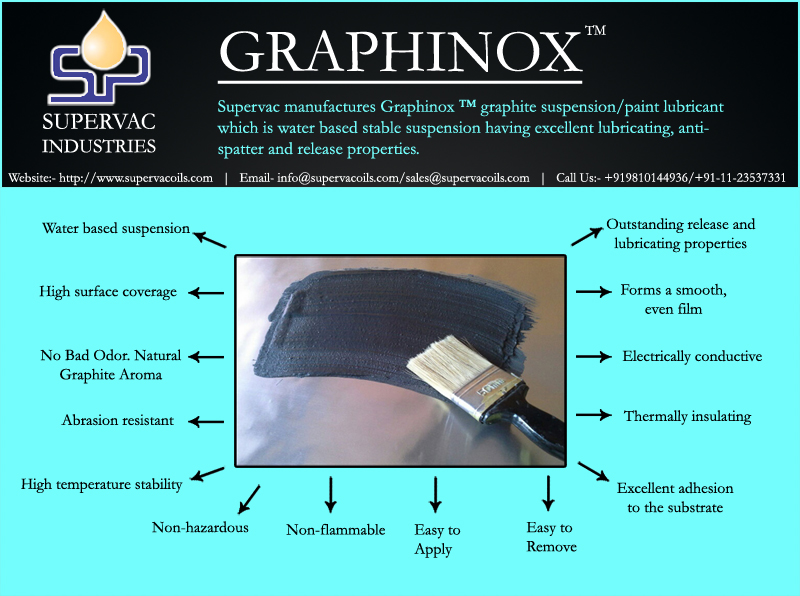

Graphinox ™- Graphite Coating

Graphite coating ‘Graphinox’ is patented water based suspension by Supervac Industries comprising ultra-fine graphite particles and inorganic binders. This specialty graphite coating has been specially formulated to protect metals from corrosion and wear.

It is ideal for vacuum applications since on drying, Graphinox graphite coating does not emit vacuum-interfering moisture or gases. When coated on molds and components, it forms a semi-permanent barrier and protects them from oxidation. Graphinox is also ideal for coating graphite crucibles and fixtures for metallurgical processing. Graphinox can be used to protect graphite electrodes used in an arc- melting furnaces.

Graphinox graphite coating is absolutely non-flammable in nature. This semi-permanent coating can be applied using a brush, roller, dip or spray coated. As and when required, Graphinox can be easily removed manually with a clean wet cloth.

What GRAPHINOX delivers

- A smooth, even film with fine graphite particles, on any surface.

- A semi-permanent film with excellent stick ability.

- Can be easily applied with a brush or roller.

- Can be easily removed with a clean wet cloth.

- No bad order - only natural graphite aroma.

- Easily withstands high temperatures.

- Electrically conductive.

- Thermally insulating.

- Non-flammable.

- Absolutely safe for all.

Your Benefits

- Only graphite suspension in the world made of synthetic graphite.

- 17.3% more surface coverage.

- No water separation; Easy Application.

- 21.9% Better stick-ability.

- Up to 73% price saving.

- Ready stock available 24x7.

- Reliable worldwide shipping.

- 100% MONEY BACK GUARANTEE

Specifications of Graphite Coating - Graphinox

| Property | Value |

|---|---|

| Base | Water Based |

| Color | Black |

| Viscosity | Suspension |

| Powder Constituent | Graphite Powder |

| Solid Content | ≤35% |

| Density | 1.3 |

| Graphite Particle Size | ≤5Microns |

| Flash Point | None |

| Working Temperature | ≤400ºC In Air ≤800ºC in Vacuum |

| Packing | 25Kg – 50Kg Plastic Drums |

Proper mixing and application of Graphinox (Graphite Suspension - Brand Supervac)

Infographics of Graphite Coating - Graphinox

Proper mixing and application of Graphinox (Graphite Suspension - Brand Supervac)

Infographics of Graphite Coating - Graphinox

How to apply Graphite Coating - Graphinox

Graphinox can be applied using an ordinary flat brush or roller. It can be used in its suspension form or if desired, can be diluted with demineralized, distilled or soft water, before being applied on the substrate. The following directions should be followed before using Graphinox-

- The suspension should be mixed properly with hand or a blender (set on a slow speed) before being applied or mixing water.

- Make sure the container is covered properly with the lid after each use to prevent evaporation of water from the suspension.

- Mixing of the water should be done slowly and uniformly.

- The area on which Graphinox is to be applied should be clean, dry and rid of all grease, oil, paint or lacquer before coating.

- Depending upon the room temperature and the humidity level, a coat of Graphinox will take about 10 minutes to dry completely to touch.

- In case more than one coat of the suspension is to be applied, wait for the first coat to dry completely before applying the next one.

Graphinox sticks effectively and effortlessly to fabric, glass, plastics, rubber, copper alloys, steel, aluminum and other metals with very little pretreatment.

Few of our Clients

What Our Clients are Saying About Us

Holostik India Ltd

(World’s largest holograms manufacturer)

We consider your Products and services as an added asset to our company

Dheeraj Gandhi Manager – Procurement February 15, 2017

Uflex Ltd.

(World’s largest metallizer)

Supervac industries have made a name for themselves which shows in their world class quality products.

Sunil Gupta General Manager (Purchase) February 15, 2017

Sunrise Polypack Pvt. Ltd

(Polyster Film Metallizer)

We acknowledge and value your work culture, professional ethics and after sales service and support of your team members for on time delivery of quality products.

Devendra Agarwal Director February 17, 2017

Shankar polymer Pvt. Ltd.

(Largest PVC Metallizer)

Supervac, not only provides us with metallizing consumables but also with rich subject knowledge and free technical support.

Sandeep Sharma Director February 17, 2017

First Vac Met Corporation Pvt Ltd

(One of India’s oldest metallizer)

Main advantage of dealing with Supervac Industries is inventory is less, same way investment is less compare to import these products from Europe and USA. We forgot to import metallizing products after dealing with Supervac Industries.

Rajiv Jariwala Managing Director February 17, 2017

DADA ENERGIES LTD.

(Oldest Capacitors Films Metallizers)

You are a dependable vendor who meets our quality, quantity and supply schedules diligently, while offering competitive pricing.

Pradeep Kumar. B President February 23, 2017

Lumax Industries Limited

We have been dealing with Supervac Industries since last 9 years. We are using there World class quality products such as Booster Pump Oils, Silicon Oil etc. They are giving us free technical support also when we required.

We wish to continue our association with you in the long run also we wish them great success and best luck for future endeavours.

Sajjan Singh Ahlawat Plant Head March 6, 2017

Kanodia Technoplast Ltd

We have been your customer for last three years for Graphite Paint and Graphite Tape. The Excellent quality of your products and timely delivery make you our preferred supplier. Keep on the good work.

Rajesh Handu GM March 7, 2017

FAQ's

How is Graphinox different from normal graphite suspension?

Graphinox is a cutting edge technology product. It has better adhesion, better barrier formation and better spreadability. This makes it far superior to normal graphite suspension.

Can I add water to Graphinox?

Graphinox is supplied in ready-to-use formulation and no water addition is required. If however you do want to add water then distilled water should be added in small quantities. After each addition it should be thoroughly mixed to obtain a homogeneous suspension.