Q.1 What is a Roughing Pump?

Ans. A Roughing Pump is nothing but an ordinary Rotary vacuum pump which is used to evacuate the vacuum system initially. After a roughing pump creates vacuum of minimum 1×10-2 Torr, the valve systems changes settings and pumps like Booster Pump and Diffusion Pump are connected to system to create higher vacuum.

Q.2 What should be the basic properties of rotary vacuum pump ?

Ans. Rotary vacuum pump must have following properties:-

- Low vapor pressure of less than 1×10-3 Torr.

- Should have viscosity between 65 to 80 cst at 40oC.

- Should not contain corrosive elements like sulphur.

- Should be resistant to oxidation.

- Viscosity of the should not change much with change of temperature.

Q.3 Which is better – synthetic rotary vacuum pump or mineral vacuum pump ?

Ans. Synthetic rotary vacuum pump oils give higher vacuum, create vacuum faster and have longer working life. In addition, synthetic rotary vacuum pump oil preserves and protects the pump interiors. So these next generation synthetic oils are superior to commonly used organic rotary vacuum pump oils. The latter is used only where cost is an issue. Supervac Industries manufactures both synthetic as well as mineral rotary vacuum pump oils – SV-77 and SV-68 respectively.

Q.4 Can I use simple hydraulic oil for my rotary vacuum pump in place of rotary vacuum pump oil?

Ans. No, you should never do that as this can seriously damage your rotary pump. Rotary vacuum pump oil is not an ordinary lubricant. It is a special fluid manufactured with thermal and oxidative stability. Unlike hydraulic oil, rotary vacuum pump oil has a low vapor pressure. It is therefore absolutely different from normal hydraulic oil or motor oil.

Q.5 Can I use simple motor/engine oil for my Rotary Vacuum Pump?

Ans. Never ever use motor/engine oil for your Rotary vacuum pump. People tend to make this mistake so very often only to end up regretting eventually. Motor oils are lubricants designed for automobile engines which work under different principles whereas rotary vacuum pump oils are specialty fluids manufactured keeping in mind the requirements of a vacuum pump. Motor oils have a different viscosity from vacuum pump oils and have no vacuum properties at all. Motor oils carry various additives like rust inhibitors and anti-corrosion compounds. When put in the rotary pump, under low pressure and high temperature, these additives separate from the base fluid and cling to the insides of the pump as sticky/gummy solids. This affects the vacuum pressure and harms the pump. Under high temperature of the vacuum pump, motor oils/hydraulic oils start releasing vapors, thus bringing down the vacuum, where as good quality rotary vacuum pump oils do not release any vapors. Supervac manufactures high quality Synthetic Rotary Vacuum Pump Fluid- SV-77, which is a boon in terms of vacuum formation and pump maintenance.

Q.6 Do Roughing/rotary pumps need topping up of vacuum pump oil?

Ans. Rotary vacuum pumps lose a small amount of vacuum oil in the form of oil mist. This loss is pronounced in initial (roughing) phase. To make up for this loss of oil it is advisable to top up rotary vacuum pump oil from time to time.

Q.7 Will Rotary vacuum pump oil used in Kinney pump and Stroke pump ( both are roughing pumps) be the same or different?

Ans. Vacuum pumps as well as vacuum pump oils are made as per international specifications. So a good rotary vacuum pump oil will be suitable for all/any rotary vacuum pump made anywhere in the world and by any manufacturer.

Just like the same petrol works for cars made by Honda, Suzuki, Audi, Toyota or any other brand.

Q.8 What is a two stage rotary vacuum pump?

Ans. A Rotary vacuum pump works by mechanically compressing and pushing out the air from inlet to outlet. The outlet pressure therefore has to be higher than atmospheric pressure for exhaust to take place. In two stages rotary pump the outlet of one chamber is connected to inlet of next chamber. This increases the compression and makes the air exhaust possible.

Majority of rotary pumps are two stage rotary pumps.

Q.9 How do I know that I need to change the oil of my rotary pump?

Ans. In vacuum industry practices for vacuum oil change vary widely.

Usually one of these three reasons trigger oil change:-

- Rotary pump starts taking longer to create vacuum or is unable to reach the desired vacuum level.

- Color of oil changes from transparent or golden yellow to dark brown indicating oxidation.

- Some engineers prefer to change oil after a fixed number of working hour which are either recommended by manufacturer or are based on experience.

Q.10 Can I recycle my rotary vacuum pump oil?

Ans. No, rotary vacuum pump oil cannot be recycled. This is because vacuum pump oils work under very demanding conditions. Used vacuum oil, even if recycled, will still be carrying various contaminants. For the safety of expensive vacuum pump, used oil is best discarded.

Q.11 What are the reasons of noise in rotary vacuum pump?

Ans. Normally rotary pumps work noiselessly.

Noise in rotary vacuum pump could be because of following reasons:-

- Excessive gas load because of some leak in system. This may also be accompanied be release of oil mist from pump.

- Some foreign object lodged in rotary pump. This will cause intermittent, loud noise.

- Worn out ball bearings. This causes continuous noise.

Q.12 What is the normal working temperature of a rotary vacuum pump?

Ans. Normal working temperature of rotary pump is about 80o C.

Q.13 My rotary pump overheats sometimes. Is this serious?

Ans. Yes, this is serious as pump can get seriously damaged if temperature of pump exceeds 100oC. Rotary pumps need to be run in well-ventilated areas and in case of extremely hot climates, as is common in India, use a fan to cool the pump externally. Overheated pumps will not give the required vacuum and thus unduly affect either the working of diffusion pump or the entire process. Also, the oil in an overheated pump will turn less viscous (too thin) and will not lubricate the pump interiors well; thereby leading to pump failure.

Q.14 What is gas ballast in rotary vacuum pump?

Ans. Since rotary vacuum pump creates vacuum by positive displacement and compression of air so during operation of this pump some water vapors condense to water and mix with vacuum oil. This reduces the vacuum.

Some pumps are equipped with gas ballast mechanism. This mechanism allows some air to flow into compression portion of pump cycle, diluting the water vapor. This causes fewer tendencies of water vapors to condense. This is called gas ballasting.

Q.15 Do vane type rotary pump and piston type rotary pump require different rotary vacuum pump oils?

Ans. In both vane type rotary pump and piston type rotary pumps, function of vacuum oil is to provide lubrication. At the same time for both these pumps the rotary vacuum pump oil should have a low vapor pressure and good viscosity stability.

Since both types of pumps require same characteristics of vacuum oil so the same vacuum oil is used for both these types of pumps.

Q.16 How do piston pumps work?

Piston Rotary Vacuum Pump

Ans. Piston pump is a type of Rotary Vacuum Pump. This pump works on a principle of drawing in and compressing of gas to exhaust it to atmosphere. It has an eccentric circular piston that rotates around the cylinder to create vacuum. This pump requires a Rotary Vacuum pump oil seal between the metal surfaces of the piston to separate the incoming and exhausting gas in the pump. The circular piston, rotating around the pump sucks in air from the chamber, compresses it and drives it out from the pump to create vacuum. Rotary Vacuum Pump oil provides lubrication also.

Q.17 What is a dry rotary vacuum pump. Compared to oil-sealed pump, is it economical to use?

Dry rotary vacuum pump

Ans. A dry pump does not depend on Rotary Vacuum Pump Oil for its operation. In this pump a set of spirals draw air in to the center of spiral, continuously compressing it. Air thus compressed finally exits from the center of spiral. These spirals are normally made of Ceramic materials.

Because of very high cost this pump is not very popular in vacuum industry and is used only where oil free vacuum is essential.

Q.18 Oil rotary vacuum pump or dry vacuum pump – Which works out cheaper?

Ans. A conventional rotary vacuum pump using rotary vacuum pump oil works out cheaper. Dry pump have a very high cost because of ceramic components used in them. Dry pumps are mainly used in industries like semi conductor industry where cost is not of much importance.

Q.19 What is Holding Pump?

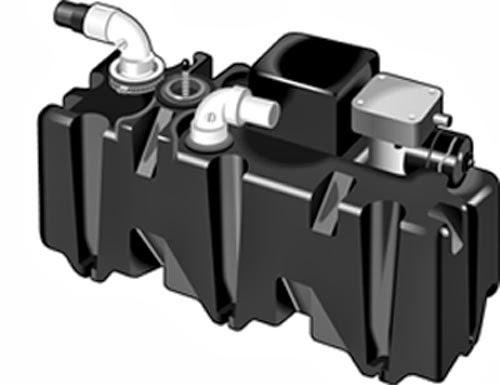

Holding vacuum pump

Ans. Holding pump is a simple rotary vacuum pump of small capacity. Its function is to create holding vacuum for diffusion pump, hence the name holding pump. It is invariably connected to diffusion pump and not directly to the vacuum chamber.

Q.20 Why should I buy rotary vacuum pump oil from Supervac Industries?

Ans. Supervac Industries, New Delhi, India is a reputed and trusted supplier of Rotary Vacuum pump oil. More than 90% of companies using vacuum systems in India are buying vacuum consumables from Supervac Industries for more than 15 years.